If you need to connect an exhaust pipe and do not have a welder, there are a several methods to get the job done.

While welding joints together is often done by shops, using U-bolts and other connection techniques is also wildly used.

In fact, whole exhaust kits can be bolted together without welding and work just as well.

Below are the best options for connecting up an exhaust.

How To Size Exhaust Pipe

Before buying any components to bolt an exhaust together, be sure to get the correct dimensions.

To size, an exhaust pipe measures the diameter with a tape measure.

If the pipe is not circular but squeezed together, use a string to go around the pipe, measure the string and then divide by 3.14 to get the dimension.

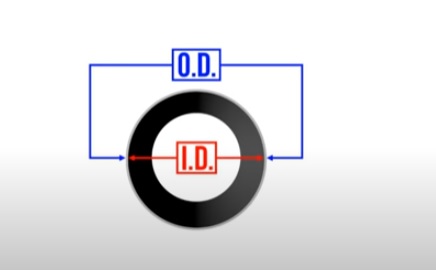

An exhaust pipe has two measurements Outer Dimension (OD) and Inner Dimension (ID).

The two measurements will be listed as the same, but one is slightly bigger to overlap with another pipe.

When the correct pipe sizes are used bolting them together works very well. If the wrong sizes are used, it can cause them to leak.

Be sure to get the right-sized pipe components, and the system should bolt together with no leaks.

*This site contains affiliate links for which a commission earned.

3 Ways to Connect Exhaust Pipes Without Welding

- U-Bolt Exhaust Clamp

- Band Sleeve Clamp

- Flexible Braided Pipe

U-Bolt clamps are widely used to connect exhaust pipes together.

Entire exhaust kits can be bought and the pipes all fit together using U-Bolts.

One pipe will need to have a flare and fit over the other, or another option will need to be used.

Pre-built pipe can also be bought that along with U-Bolts replace or modify a section.

Example U-Bolt Exhaust Clamp on Amazon

Exhaust-Mate 35794 3″ Heavy Duty U-Bolt Exhaust Clamp

A band clamp is a sleeve that goes around the pipe and is tightened until both pipes are connected.

They are very useful when the pipe being connected is straight but not so good on a bend or curve.

The clamps can be bought as narrow or wide units with more width.

If you are replacing or combining two old pipes, Copper RTV is often used to help it to seal.

New piping will not need the RTV and will simply bolt together.

Example Band Sleeve Clamp on Amazon

EVIL ENERGY 2.5 Inch 2 1/2 Butt Joint Exhaust Band Clamp Sleeve Stainless Steel 2pcs

Braided flexible exhaust pipe is also a good option, especially when a bend needs to be made.

They can have a short or long length depending on what is needed and can be clamped into place with U-bolts.

Flex pipe is a good option in many scenarios and works well for a very long time.

Example Flexible Braid Pipe on Amazon

2PCS Exhaust Flex Pipe Stainless Steel Double Braid 2″ x 6″ w/Ends 10″ Long

Summary

If you need to connect an exhaust together without welding, there are three main options available.

This includes the U-bolts, band clamp, and flex pipe.

Be sure to measure your exhaust at different points to get the right dimensions before buying any components.

Getting a good fit is necessary when bolting pipes together to get a good seal and no leaks.

Do you have a favorite method for connecting exhaust pipes without welding? Let us know your thoughts below.

The rear of my catalytic converter connection is rusted out with only about a third left at the top where the exhaust connects I have no welder and to have it welded is expensive on me rite now is there a way to extend this connection so it will fix it. Can I use JB WELD to maybe build it up to work idk. But it is way to loud rite now 95 GMC SIERRA 1500 EXTENDED CAB. And I appreciate your video. I wish I could show you what I’m talking about…1 more thing could I maybe get a smaller diameter pipe and stick it inside the converter and slide it inside the rest of the exhaust maybe 2 inches then JB WELD it together and then exhaust wrap it. I mean I really don’t know lol please help. My wife is complaining to me (you know what that means lol) HELP ME…

Helo I have a 97 Ford f150 and I have been a victim of my Cadillac converters being stolen off it. They cut the pipe from my pipe going into the motor and the pipe that comes across the bottom where the two pipes connected has been taken also. So, I was thinking about temporally putting pipes on it in order to drive it to quieten it down . But need to know how I could do that with that bottom pipe gone also how can I connect both pipes together in order for it to flow down to the one pipe that leads out to my muffler in the back I need all the advice I can get . I got to get my truck driveable I been walking back and forth to work everyday and jus need a way to make it driveable until I get those converters on it replaced thanks

I would measure the pipe diameter and go to a local Auto Parts store to see what they have available and the prices. Often prices are lower online, but it will give you an idea of what to get.

Will a 2.25″ inside diameter pipe fit over a 2.25″ outside diameter pipe?