When it comes to auto body work, deep dents are not easy to get out and either need to be hit from the back or pulled out.

Since many dents cant be reached from the back, dent puller options are often looked at as the best method.

One of these methods is called a Stud Welder Dent Puller, which welds a small stud to the metal of a vehicle which is then pulled on to pull the dent out.

If you have no welding experience, not to worry, as there is no skill involved.

Basically, after the small stud is inserted into a unit, a trigger is pulled for 1-2 seconds which melts the small stud into the sheet metal of the car or truck.

The welded-on stud is then pulled on to get the dent out.

Needing some deep dents pulled, I recently broke down and bought a unit.

The unit I decided on was the H & S Autoshot 4550 Starter Plus Stud Welder Kit.

It is a starter kit edition that comes with everything necessary to use a stud welder, including 500 flexport welding studs to get started.

How To Use a Stud Welder Dent Puller

Using a stud welder dent puller is fairly simple; just be sure not to hold it for too long and burn a hole through the metal.

A few practice tests will be best on a piece of old metal

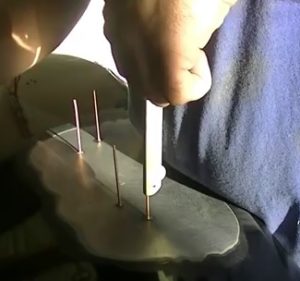

Get one of the studs and insert it into the end of the welder.

The tip is pressed against metal and held for 1 second, and it welds a stud to it. Don’t hold it too long, as a small hole will burn through the metal. Practicing first on old metal would be best.

I tested it out and practiced on an old piece of metal before using it on a vehicle.

It really is simple to use; multiple studs will need to be welded onto a big dent to pull it out.

How Well Does a Stud Welder Dent Puller Work?

After you understand the process, it does a good job.

Using an attachment that pulls on the dent is best, in my opinion.

I found that tapping with a hammer around the damaged area and pulling at the same time worked best for me.

Some people use the slide hammer puller that is included in the kit or has one lying around. They have a tendency to pull the studs off immediately, in my opinion. Often it is better to use vise-grips or other tools attached to the welded studs and pull on them to get a dent out.

Again there is no set method, and what works for one person may not work for another. For some, the slide hammer may be best.

As with anything, some skill and practice are necessary to get good at it. It is a straightforward process of welding on a stud and pulling on it to get a dent back out.

The main key is to get a stud to hold to the dent so it can be pulled out. Getting down to bare metal will be necessary, so it can get a good weld.

*This site contains affiliate links for which a commission earned.

Read More Reviews Here on Amazon

H & S Autoshot 4550 Starter Plus Stud Welder Kit , yellow

Summary

Using a stud welder dent puller is a good method to remove difficult dents.

I am more than happy with my purchase and plan to get much more use from it.

There are many YouTube videos that show the different methods people have for pulling on a stud, so no doubt you will find a method that works for you.

The H & S Autoshot 4550 is a low-cost budget kit that should work well enough for the DIY auto-body man.

There are more expensive units for those looking for a top-end unit.

As always, be sure to read the reviews on Amazon or elsewhere to be sure a unit is a good fit for you.

These type of stud welders work great it the dent is not really deep or large, over 8″ in diameter. If there are a lot of deep creases or sharp creases, panel replacement I’d probably the best approach, especially if your not skilled at body repair. Either way, you first have to sand/grind all of the paint off of the dent. You’ll have to do this anyways for the bondo to adhere to the sheet metal. The stud is the positive electrode and the outer ring is the negative. Both have to make good contact to weld the stud. Pull the trigger about 1-2 seconds to get a good weld. Metal thickness will control timing. Too long and you’ll burn a hole in the panel just like welding. Too short, and the stud won’t stick and will pull off too easily.

I reuse the studs by using a nail nipper typically used to cut nails flush to the surface. You don’t cut the stud, rather you use the cutters to firmly grip the head of the stud and twist it back and forth to remove it. Even if you don’t reuse them, it gives a nice flush finish to work with vs grinding them off. Grinding them creates too much concentrated heat that can warp the panel an degrade the metal even further.

I had no idea that stud welders could be used to pull dents. Our car was recently severely damaged after a recent accident. I wonder if a stud welder could help to repair everything properly.

Will this be any good for pulling a dent on a box frame? I planned on heating the dent in the frame after welding a stud to it so i will have an easier time removing the dent from the thick material.

Just bought one, I tried it on a piece of sheet metal. I only held the trigger for one second. Because I’m using a 15 amp. Breaker, it welded the stud on enough that I had to twist it off. I think it’s great. Also for anybody reading this please use the recommed breaker. For safety reasons.